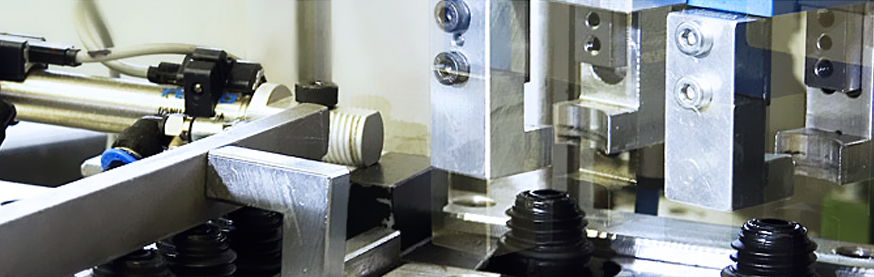

Our manufacturing facilities offer versatile, heavy duty machinery on a 2,000 m² production site. We work with modern CNC-controlled milling and turning machines. The fully automated processes are kind to the materials, and ensure reliable, precise and efficient production even under peak load conditions. We can gladly send you a detailed overview of our machine capacities on request.

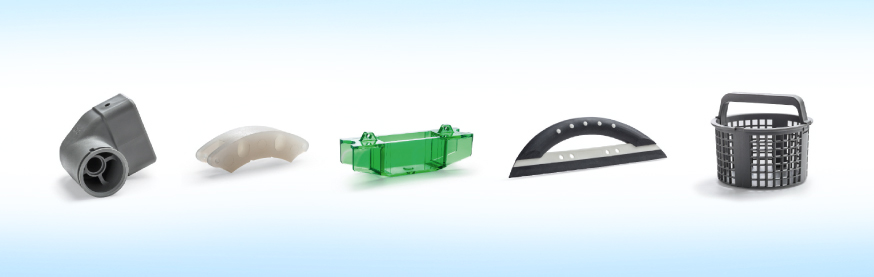

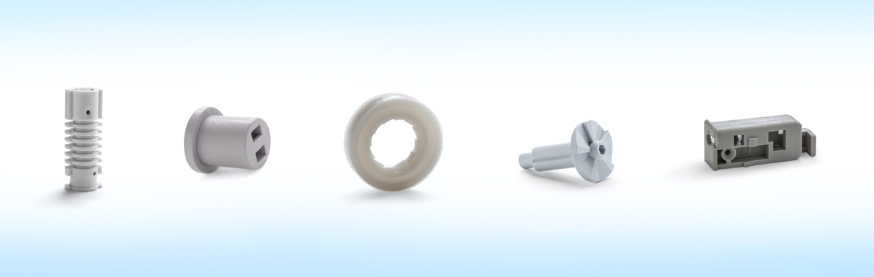

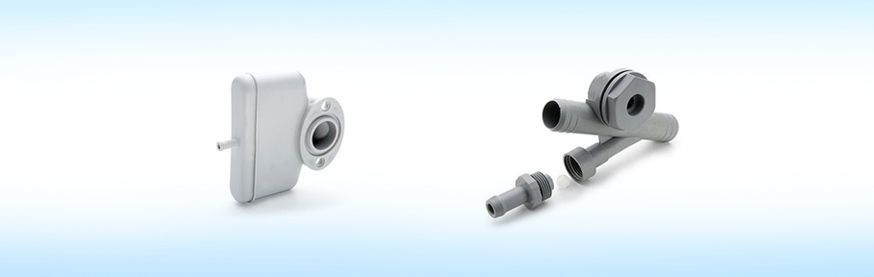

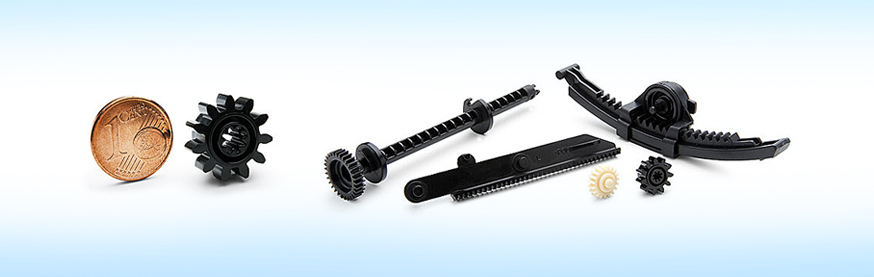

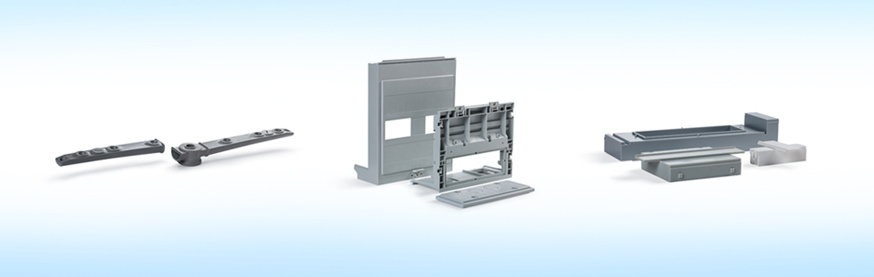

Together with conventional one-component injection moulding, we also perform the following special procedures:

In interval injection moulding, two plastic components are injected alternately into the cavities. The interval technique creates a colour effect as the two plastics merge, with no clear colour limits as a result of the mixing process.

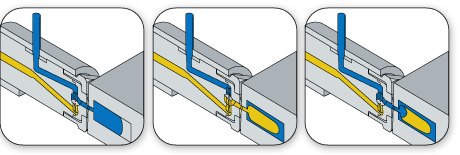

Here an enclosed core is injected into an outer skin component. The skin component can consist of a different compatible material than the core, or the same material which has been modified. Frequent applications are visible mouldings with a visually upgrade outer skin and core made of regenerated plastic, or technical parts with a hard core and modified surface to improve the haptic properties.

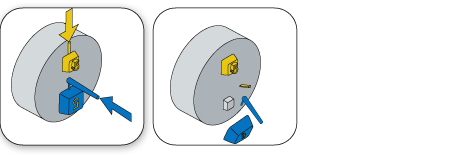

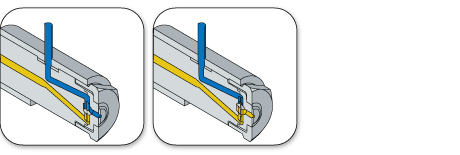

In this case, moving cores or inserts initially seal cavities in the tool, and open them again later. Composite injection moulding can be used for two and more components.

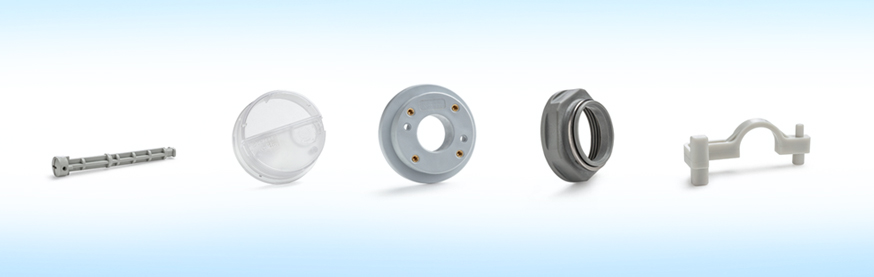

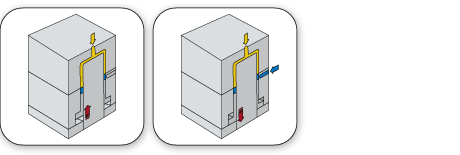

Injection moulding around inlay parts produces mouldings which usually cannot be produced by conventional injection moulding because of integrating functions in the plastic part, for example. This results in composite parts where various materials are combined together with the plastic. These combinations are required to combine differing properties in terms of strength, conductivity, insulation or weight.